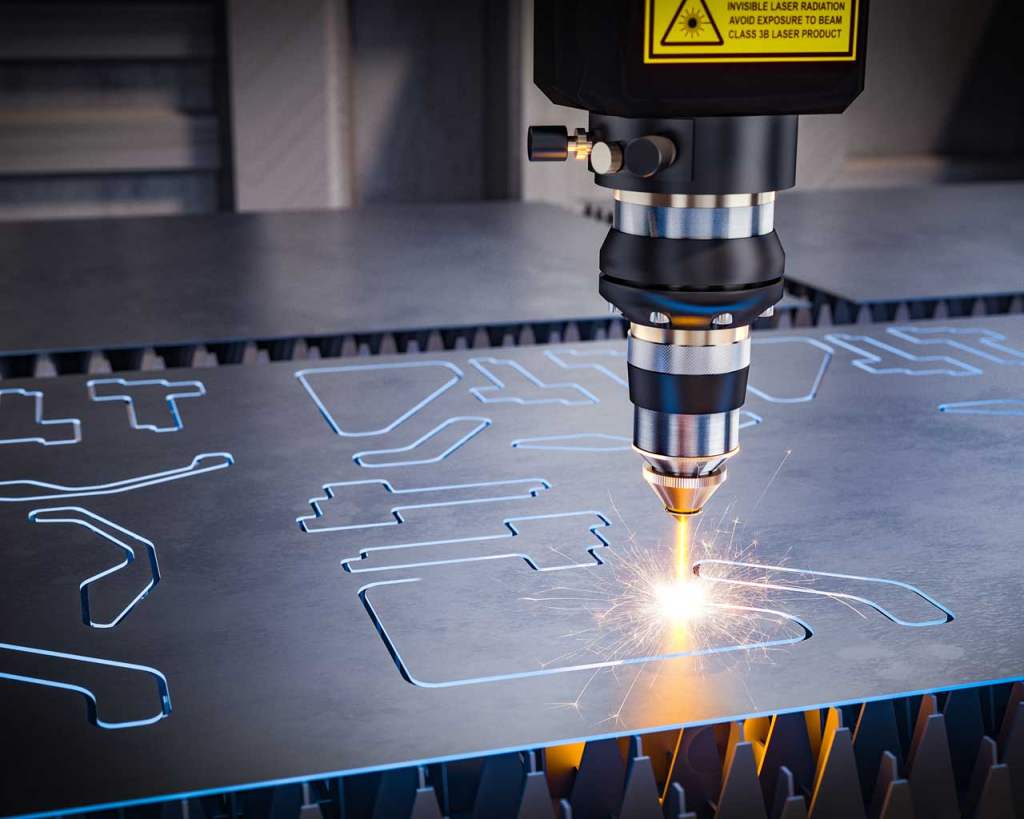

Laser cutting solutions have emerged while the top of detail on earth of fabrication and design. Utilising the power of aimed beams of light, laser cutting is just a technological marvel that delivers unmatched reliability and versatility to many industries. In this exploration, we search in to the complicated earth of laser cutting companies, understanding their purposes, advantages, and the major impact they have on the realms of manufacturing, style, and beyond.

At the key of laser chopping lies the capacity to achieve reductions of extraordinary precision, enabling the generation of intricate types and complicated patterns that were when tough to reach through standard cutting methods. The laser beam’s concentrated power makes for small product wastage, ensuring performance and cost-effectiveness in generation processes. This detail reaches a varied range of components, including metals, materials, wood, textiles, and more, making laser cutting a flexible alternative for different industries.

The benefits of laser chopping are manifold, particularly in manufacturing. The procedure helps the quick prototyping of patterns, facilitating rapid iterations and adjustments. That agility is priceless in industries where time-to-market is really a critical factor. More over, laser cutting enables the generation of highly detailed parts with clean sides, adding to the overall quality and operation of the end product. From automotive areas to delicate electric parts, laser cutting has become indispensable in the manufacturing landscape.

One of the standout top features of laser chopping solutions is the ability to utilize a varied range of materials. Laser cutters can simply slice through metals, giving detail in purposes like page metal fabrication and complex material artwork. Simultaneously, the same laser cutter can gently etch intricate habits on fine materials such as for instance report or fabric, showcasing the versatility that units laser cutting apart from traditional cutting methods.

The influence of laser cutting runs beyond production to the realms of design and creativity. Artists and makers control laser cutting companies to breathe living into their thoughts, making step-by-step sculptures, architectural designs, and bespoke parts that push the limits of what is achievable. The finesse with which laser cutters handle products allows for the understanding of complex habits, personalized engravings, and three-dimensional models, opening up new opportunities for innovative expression.

As well as detail, laser cutting services present efficiency and speed. The non-contact character of the procedure eliminates the necessity for bodily software improvements, lowering downtime and permitting constant and uninterrupted cutting. That efficiency is very important in large-scale production, wherever quick recovery times are necessary for conference industry demands.

The introduction of laser cutting has also ushered in a new era of modification and personalization. Whether it’s crafting complex models on wedding invitations or making unique signage for firms, laser chopping companies encourage people and corporations likewise to generate a touch of personalization within their projects. The engineering permits the conclusion of stainless steel and detail by detail styles with reliability and repeatability, ensuring that every item is just a work of detail and artistry.

To conclude, laser chopping services symbolize a pinnacle of precision, usefulness, and effectiveness in the realms of production and design. From the generation of intricate components in commercial adjustments to the recognition of artistic visions in creative spots, laser cutting is becoming an crucial tool. The relationship of technical class and creative freedom makes laser cutting companies a transformative power, unlocking new opportunities and placing new requirements of accuracy on the planet of manufacturing and design.